Plant Layout & Design

Introduction

Once you have decided on where to locate your pharmaceutical company, the next important thing you need to do is to plan a suitable layout for your pharmaceutical plant. While designing a pharmaceutical plant, you need to understand and follow the basic regulatory requirements for the construction of a pharmaceutical plant.

A good plant layout and design should aim at minimizing the risk of errors and permit effective cleaning and maintenance in other to avoid cross-contamination, build-up of dust or dirt and in general, any adverse effect on the products.

Features of a good pharmaceutical plant layout:

- There should be adequate floor space for machines installation and utilization

- The machines should be properly arranged to facilitate minimum material handling, which is necessary for low cost processing.

- The layout should facilitate smooth and continuous flow of production process from one point to another without any form of delay

- It must incorporate adequate health, safety and security features such as first aid box, fire extinguisher, emergency exit and access point

- A good layout should allow effective supervision, coordination and control of the production processes

- There should be room for adjustment and modifications whenever the need arises.

Turnkey Project Management

The idea of Turnkey Project Management (TPM) for complex technical and construction projects is to reduce the client’s costs and the effort for observing, individual coordination and planning to a minimum.

Turnkey project management means that our clients will receive a total turnkey approach to their investment project. Under the project idea, the Project need will be included and completely responsible for all technical coordination tasks with all other trades and client users.

Drawings

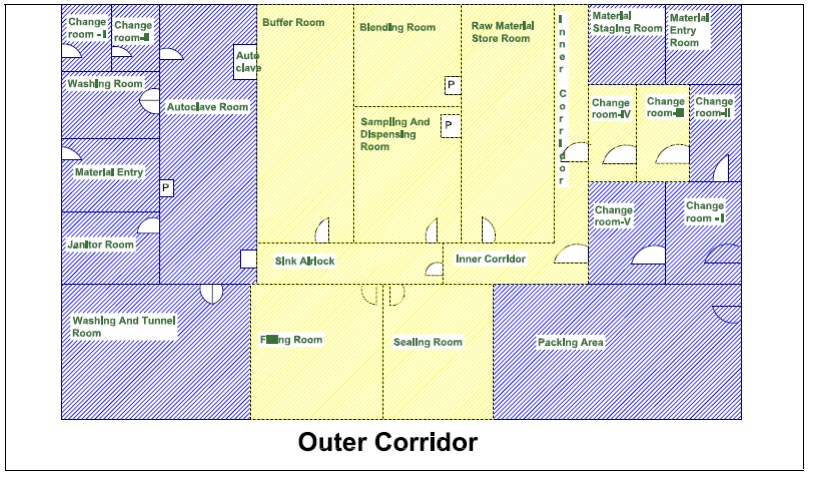

Injection Section

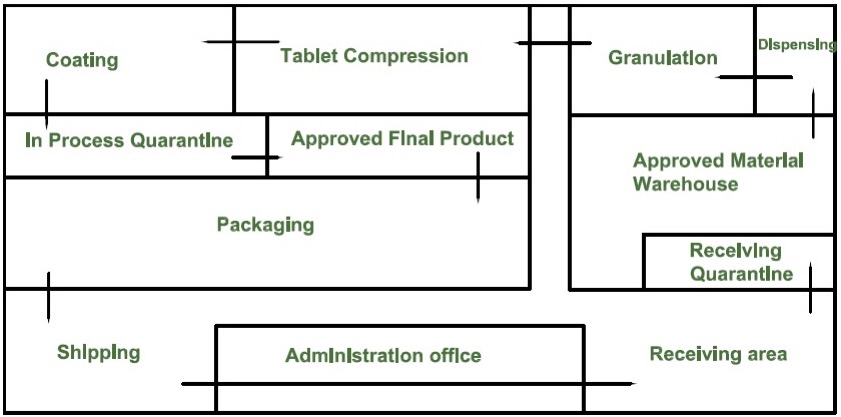

Tablet Section

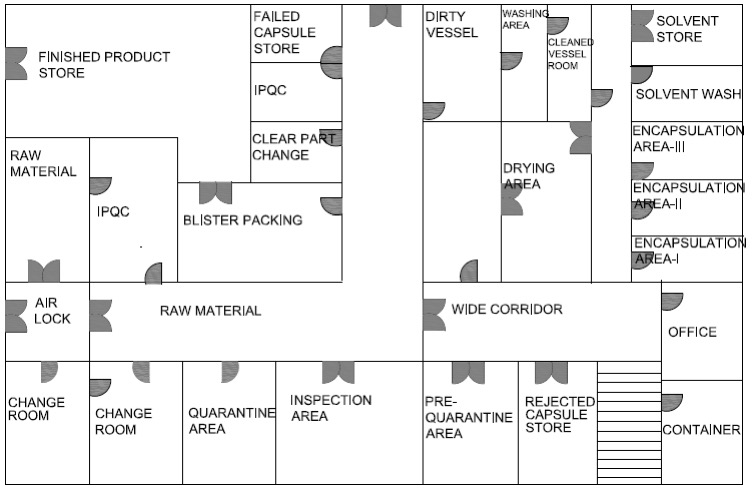

Capsule Section